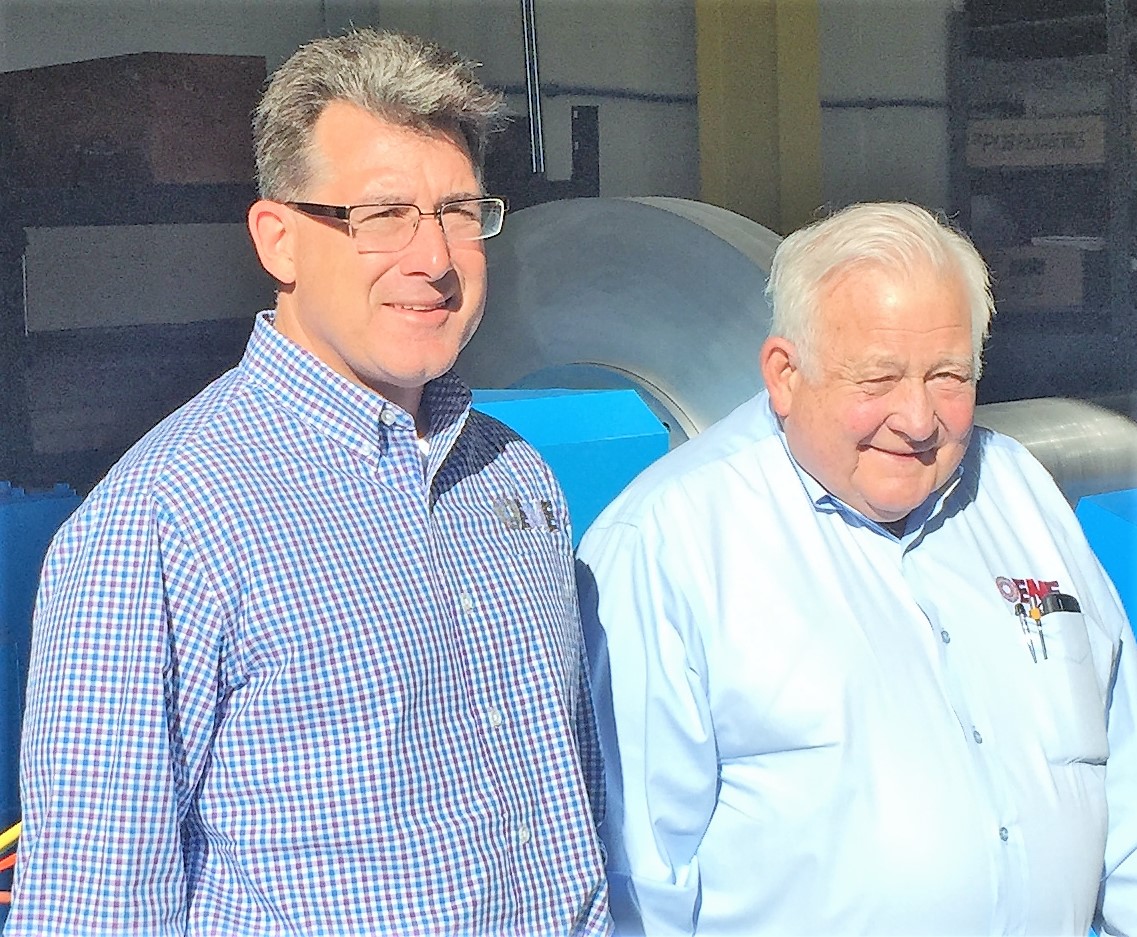

Passing The Baton – Alan J. Spisak, P.E., President/CEO

– Alan J. Spisak, P.E., President/CEO

How do you fill the shoes of a legend? As a young engineer fresh out of college, I joined EME. Like many individuals transitioning from the role of an engineering student to that of a professional, I wasn’t certain what ‘being an engineer’ meant. I had interned some for my father Andy, however I had not been a part of the business day-to-day.

It soon became apparent to me that my father, his partner Don Reilly, and the associates with whom he worked all had a sincere affection for the art of engineering. Many of our associates were technical leaders in their fields; Al Raimondi, Ph.D., the well known tribologist, Leonard Fennell, a pioneer in turbo generator design methods, Barry Sargent, lead designer for the largest US hydro generator – the list continues. I came to appreciate that the, once young engineers like me, as well as the new engineers we hired, were standing on the shoulders of giants; engineers and scientists who had derived and developed the protocols and approaches which would become integral to the Power Generation Industry.

As I look forward, one of the things which drives, guides, and directs me is maintaining the engineering roots of EME. Over the past 35 years we have enjoyed supporting and resolving some fascinating challenges within the Power Generation and in other industries (see “35 Years from My View” in this edition of Engineering Matters). In fact, EME was recently awarded a patent for our approach in using a single prime mover to start-up (2) cross-compound generators which had been converted to a synchronous condenser.

This brings me to “What’s Next”. As I consider our history of pursuing excellence in engineering with a passion and where we might be able to apply those capabilities, the idea of expanding our engagement in the industry through offering of physical services to compliment our engineering services comes to mind. The generation and industrial markets have become even more competitive; demanding higher levels of reliability for their equipment and the highest quality in execution of projects. I’m convinced that the way to achieve these requirements is through the application of our extensive engineering knowledge to affect engineered repairs and process improvements for our customers critical rotating equipment.

We have already been active in the Field through our Test, Inspection, Heat Run and Commissioning services. Additionally, we’ve done a number of First Of A Kind projects like the Synchronous Condenser Conversion effort for which we received a patent and the High Pressure Ventilation Modification for Brushless Exciters to prevent conductive particulate ingress to the diode wheel. EME is no stranger to tight schedules in which implementing of a solution or resolving of challenging technical issues are required.

The concept then of extrapolating our engineered projects approach to servicing of electrical generators and exciters which we have been designing and analyzing for decades is eminently logical. Our understanding of the critical characteristics for a variety of machine designs uniquely positions us to design processes, tooling and practices to ensure that this critical equipment is receiving the level of attention required to achieve optimum performance.

As we move into the next 35 years, I look forward to supporting you in whatever capacity you need; engineering consulting, generator/exciter servicing or specialty project development and execution. Please keep us in mind for all of your generator needs and don’t hesitate to call if you simply want to discuss any issue on your electro-mechanical rotating equipment.

Sincerely,

A.J. Spisak