Vibration Testing, Analysis & Troubleshooting

EME utilizes a variety of testing equipment to analyze, test and diagnose vibration issues. Proximity Probes, Siesmi Probes, multi-channel recorders and fast fourier analyzers are employed in determining resonant frequencies, mode shapes, the operating deflection shape for rotor trains as well as the magnitude and phase angle of mass imbalance.

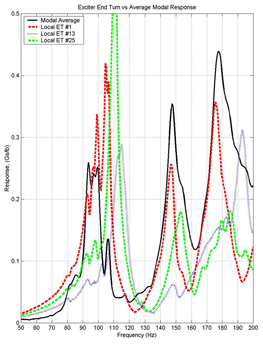

Impact Testing and Modal Analysis

Impact testing and Modal Analysis is a powerful tool used to determine the natural modes and frequencies of extended structures. It is often used to determine the natural modes of generator stator end winding “baskets”. For instance, a two pole generator end winding basket must not have an elliptical mode of vibration near twice running speed (120 Hz in North America). By impacting at a single reference location and measuring responses at both that location and an array of locations on the structure, all modes of vibration in the relevant frequency range can be discovered and visualized.

Rotor Balancing

EME routinely performs multi-plane balancing of rotors for vertical and horizontal machines. Using proximity and seismic probes, mass imbalance will typically be corrected to less than a residual amplitude of 0.002inches peak-to-peak (2 mil p-p) which is significantly lower than the ISO Zone A requirement. In addition to balancing, EME possess the necessary expertise to diagnose other rotor dynamics issues such as bearing whirl and rubs.

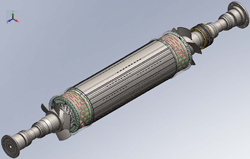

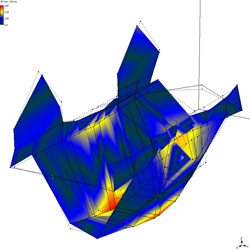

(ODS) Operating Deflecting Shape Testing

Operating Deflection Shape (ODS) testing is the dynamic equivalent of Modal Testing. By combining a geometric model with operating vibration readings, it is possible to visualize the motion of an extended structure at various frequencies. In the figure (above/below), a single accelerometer is used as a reference so that the vibration magnitude and phase of all other points (measured with a roving three-axis accelerometer) can be animated relative to that point and thus each other. The figure shows a large turbo generator housing vibration at 120 Hz. Note that if accessible, this test can be extended to include bearing proximity probes, and thus even the rotor vibration at the bearings can be seen relative to generator housing vibration.