Recently a generator experienced an overspeed (approximately 4,739 rpm) event. Typically for a 60Hz generator the rotor is designed for stresses at 20% (<4,320) overspeed. As a result, EME was asked to evaluate portions of the generator rotor (radial studs, retaining rings, forging, & wedges) to determine the stresses that existed at 4,739 rpm and aid in determining if the rotor was acceptable for continued operation. In addition to the generator rotor, concerns were raised regarding the shaft mounted exciter’s suitability for continued service.

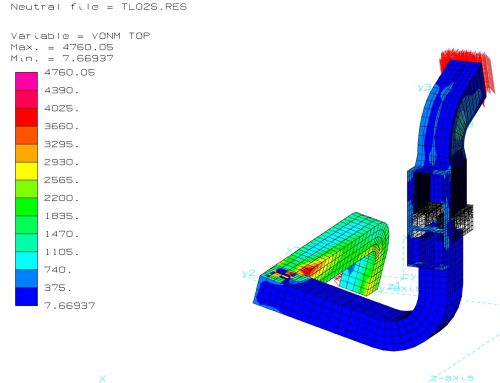

Based on evaluation, it was determined that the most prudent course of action was to strip the exciter, inspect the reusable components, and rewind the exciter to replace all copper that may have experienced excessive stress. Validation of the suitability of the exciter core after the overspeed event was performed by modeling the core with a 2D half tooth / half slot model, including the wedge slot and wedge and performing a Finite Element Stress Analysis (FEA) on the model using the slot contents as applied mass and self-loading from the centrifugal force. We were very pleased that our efforts were able to avert the expense of purchasing a new rotor and the associated lead time; we pride ourselves on keeping our customers equipment in service and extending its useful life.

The test, inspect and rewind effort included verifying diode leakage current, the forward and reverse resistance of the diodes, capacitance of the capacitors and the diode wheel insulation resistance. The mounting hub and rotating components were dye-penetrant tested to verify acceptability for re-use as well as the Parallel ring assembly which was re-silver plated. The rotor core was loop tested to verify no interlamination shorts existed and following rewind and re-banding with stainless steel, the assembly was rebalanced.

Learn more about our Brushless Exciter Capabilities at https://emeassociates.com/equipment-specialties/excitation-systems/

To find out more, about how EME applied our engineering capabilities on this project and into all aspects of our services, please contact Bob Fuller at bfuller@emeassociates.com