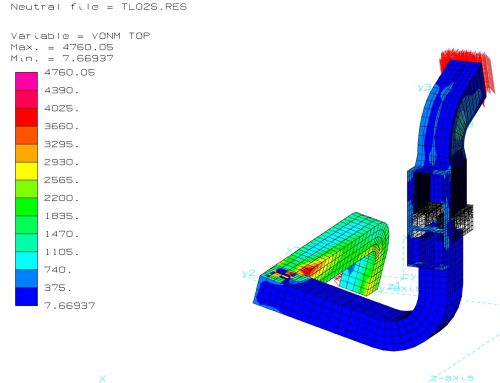

Many large hydro-generators have baffle plates on the rotor spider. The baffle plates induce and control airflow in the unit to cool the rotor rim, pole windings and primarily the stator. EME recently investigated a unit with a rotor of approximately 300 inches in diameter, which had 8 spider arms, and a span between arms of approximately 80 inches. Throughout the unit’s history, the operators have discovered cracked bolts or cracked baffle plates or both.

Why were the baffle bolts failing? What design change should be recommended?

A. Baffle plate vibration (such as a natural frequency coinciding with vortex shedding or other flow induced problems.) Change baffle plate design.

B. Lack of clearance leads to high forces on bolts – increase clearance hole diameter.

C. Spider arms bend due to operating torque, causing baffles to slide under bolt heads, leading to fatigue cracking. Modify fastening to reduce or eliminate friction.

D. Bolts aren’t tight enough, and movement causes cracking – use higher grade bolt or larger diameter bolt and more torque.

E. Bolts are rusting – switch to stainless steel.